Amid the roar of data centers, rows of servers are running day and night,and the energy consumption of fans,the key equipment that supports stable heat dissipation,is quietly becoming the focus of operating costs. Although traditional fans are heroes in heat dissipation,they are also big power consumers. Today,backward centrifugal fan technology,with its significant energy-saving and noise-reducing advantages,is bringing a quiet green revolution to the industrial field,becoming a new choice for cost reduction and efficiency improvement in high-energy consumption scenarios.

Core technology breakthrough,efficiency and quietness win-win

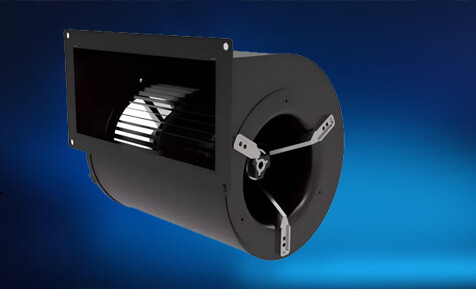

The reason why the backward centrifugal fan has attracted so much attention is its unique blade design. Unlike the common forward blades, the backward blades adopt a curved shape that conforms to the principles of aerodynamics, which greatly optimizes the airflow path and significantly reduces the internal friction and eddy current loss during air flow. The direct benefit of this design is a significant improvement in operating efficiency, especially under partial load conditions, it can still maintain efficient operation,and the comprehensive energy consumption can be reduced by 15%-25% compared with traditional fans. At the same time, the backward blade structure effectively disperses the impact of the airflow, making the fan run more smoothly and smoothly, and the aerodynamic noise generated is significantly reduced, bringing a more comfortable and quiet experience to the working environment.

Solve industry pain points and drive green manufacturing

The industrial sector has long faced the dual challenges of high energy consumption and environmental pressure. The rise of backward centrifugal fans accurately responds to these core demands. In high heat load scenarios such as steel smelting and chemical production, its excellent heat dissipation capacity ensures the safe and stable operation of the equipment; in noise-sensitive places such as large commercial buildings and hospitals, its low noise characteristics effectively improve the environmental quality. More importantly,under the guidance of the "dual carbon" goals, industrial energy-saving transformation has become an inevitable trend. Backward centrifugal fans directly reduce carbon emissions by reducing system operating energy consumption, providing a practical technical path for enterprises to practice green manufacturing and reduce energy costs, and becoming an indispensable power component in the green and low-carbon transformation of industry.

The application prospects are broad and the market continues to heat up

As energy conservation and emission reduction policies continue to increase around the world and companies are increasingly in need of refined management of operating costs, the market potential of backward centrifugal fans is accelerating. Industry analysts predict that this market segment will grow steadily at a considerable rate in the next five years. The focus of technology research and development will continue to be on more efficient impeller aerodynamic design, more intelligent frequency conversion control technology,and remote monitoring and energy efficiency management systems combined with the Internet of Things,aiming to further tap the potential for energy conservation and improve the level of equipment intelligence and user experience.

Awesome! Share to:

News

Forward-facing centrifugal fans lead the way in upgrading ventilation and air conditioning systems

Forward-facing centrifugal fans lead the way in upgrading ventilation and air conditioning systems Superior performance and quiet design for green industry and comfortable built environments

Superior performance and quiet design for green industry and comfortable built environments Duct fans revolutionize building ventilation systems and lead new trends in green buildings with high efficiency and energy savings.

Duct fans revolutionize building ventilation systems and lead new trends in green buildings with high efficiency and energy savings.

Get in Touch

*We respect your confidentiality and all information are protected.