In today's pursuit of sustainable development and refined operation, efficient, reliable, and energy-saving ventilation equipment has become a key support for industrial production and building environment. As an innovative leader in the field of fluid machinery, Force-will Technologies (Qingdao)Co,.Ltd. announced that its new generation of high-performance backward centrifugal fan series products, with breakthrough design concepts and exquisite manufacturing processes, are providing global customers with better aerodynamic solutions, significantly improving system energy efficiency, reducing operating costs, and creating a quieter and healthier environment.

Backward centrifugal technology: the cornerstone of efficiency and quietness

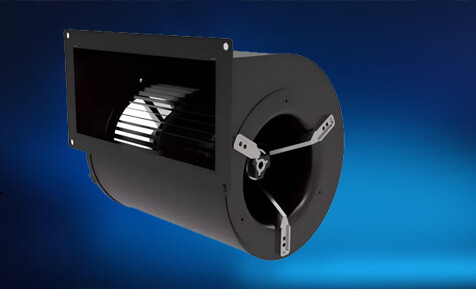

The backward centrifugal fan is famous for its unique blade design (the bending direction of the blades is opposite to the rotation direction of the impeller).

Compared to forward fans, Force-will Technologies (Qingdao)Co,.Ltd.'s backward centrifugal fan series has the following core advantages:Excellent energy efficiency: The aerodynamic design of the backward blades significantly reduces the impact and vortex losses of the airflow inside the impeller, resulting in higher energy conversion efficiency. Especially in operating conditions with high system resistance, its high efficiency range is wider, which can effectively reduce long-term power consumption and help customers achieve their "dual carbon" goals.

Ultra low noise: Optimized blade shape, precise dynamic balance, and advanced volute design make airflow flow smoother and more stable, significantly reducing aerodynamic noise and mechanical vibration from the source, providing a quieter and more comfortable operating environment, and meeting increasingly stringent environmental and occupational health requirements.

Strong and reliable: Using high-strength materials and high-precision manufacturing processes, the fan structure is sturdy, the impeller rigidity is excellent, and it has excellent overload capacity and deformation resistance. Even in harsh industrial environments or continuous operating conditions, it can maintain long-term stable and reliable operation.

Wide adaptability to working conditions: The performance curve of the backward centrifugal fan is relatively flat, and the air volume fluctuates less when the system resistance changes. It has stronger adaptability to changes in the pipeline system and operates more stably.

Widely applicable and showcasing value

Force-will Technologies (Qingdao)Co,.Ltd.'s backward centrifugal fan series products are designed flexibly, covering various air volume and pressure requirements, and can be widely used in industrial fields such as factory workshop ventilation, process cooling, dust removal systems, exhaust gas treatment (such as welding smoke and VOCs), material transportation, boiler drum/induced draft, etc.

Commercial and public buildings: Central air conditioning systems for large shopping malls, hotels, hospitals, office buildings, and subway stations for air supply/return/exhaust.

Environmental engineering: sewage treatment aeration, desulfurization and denitrification devices, etc.

Energy and electricity: gas turbine intake and exhaust, cooling tower ventilation, etc.

Special applications: clean rooms, data center cooling, and other places that require extremely high air quality and reliability.

Awesome! Share to:

News

Forward-facing centrifugal fans lead the way in upgrading ventilation and air conditioning systems

Forward-facing centrifugal fans lead the way in upgrading ventilation and air conditioning systems Superior performance and quiet design for green industry and comfortable built environments

Superior performance and quiet design for green industry and comfortable built environments Duct fans revolutionize building ventilation systems and lead new trends in green buildings with high efficiency and energy savings.

Duct fans revolutionize building ventilation systems and lead new trends in green buildings with high efficiency and energy savings.

Get in Touch

*We respect your confidentiality and all information are protected.